News

The distillation system of the reaction vessel helps Spanish enterprises break through the bottleneck of brine treatment

Customer Background

The Spanish client is engaged in the recovery and treatment of industrial brine, processing an average of 95 kilograms of brine solution per day, with a salt content of 5%. It is required to achieve the separation of salt and water through distillation and collect high-purity distilled water. The customer has a limited budget and has high requirements for the corrosion resistance, sealing performance and degree of automation of the equipment. The specific demands include:

Adopt a system of distillation in a reaction vessel and collection through condenser tubes;

Configure a vacuum pump to maintain a negative pressure of -0.1 MPa (gauge pressure) inside the reaction vessel;

After distillation is completed, a backwashing system is required to clean the crystalline salt in the reactor and collect it.

Steam heating method to ensure distillation efficiency;

The parts of the equipment that come into contact with liquids need to be corrosion-resistant.

Diagnosis of pain points

Efficiency bottleneck: The traditional open distillation method has high energy consumption, slow distillation rate, and cumbersome manual operation, with labor costs accounting for up to 40%.

Corrosion challenge: Salt water and crystalline salt have high requirements for equipment materials. Ordinary stainless steel reactor bodies are prone to corrosion, and the replacement cost is high.

The cleaning process is cumbersome: The crystalline salt adheres to the inner wall of the reactor and is difficult to clean. After each distillation, it takes 4 to 5 hours to manually scrub, which affects the production cycle.

Solution

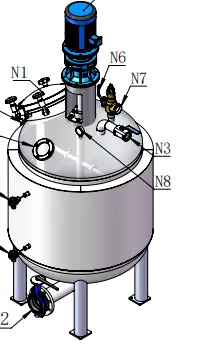

Model: JYRGF-300 Reactor Distillation System (Vacuum Negative Pressure + Steam Heating Configuration)

? Breakthroughs in core technologies

Vacuum negative pressure distillation system

Configure a rotary vane vacuum pump to precisely maintain a negative pressure environment of -0.1 MPa inside the reaction vessel, lower the boiling point of brine, increase the distillation efficiency by 50%, and reduce energy consumption by 30%.

The water vapor produced by distillation is rapidly cooled through a spiral condenser and flows into a 100L stainless steel distilled water storage tank, with a recovery rate of ≥95%.

2. Innovative design of three-layer reactor body

Outer layer: Filled with perlite insulation material and wrapped with a 304 stainless steel shell to reduce heat loss, with a surface temperature of ≤40℃, ensuring operational safety.

Middle layer: Steam-heated interlayer, which can be connected to saturated steam at 0.3-0.5MPa, with heating uniformity ±2℃.

Inner layer & stirrer: Coated with PTFE (polytetrafluoroethylene) anti-corrosion coating, resistant to strong acids, strong alkalis and salt corrosion, with a smooth surface that does not stick to crystalline salts.

3. Automatic backwashing collection system

After distillation is completed, the reactor wall is back-flushed with high-pressure water (0.8MPa). The crystalline salt is collected in a dedicated storage tank along with the water flow through a filter screen. The cleaning time is shortened to 1 hour, and the salt residue recovery rate is ≥98%.

? Economic Breakthrough

Cost advantage: The equipment procurement cost is only one-third of that of imported similar products, and the daily processing cost is reduced by 60% (compared with traditional processes).

Durability upgrade: The PTFE coating has a lifespan of 5 to 8 years, reducing the frequency of replacement; The perlite insulation layer is maintenance-free for life, saving 25,000 euros in maintenance costs annually.

Junyi Copyright ? 2025 ALL rights reserved