News

I. Customer Requirements

Raw liquid: Wastewater from marble cutting

Characteristics: Large flow rate, higher density compared to water

Flow rate: 1500L/min=90m³/h

Solid content: 12%

Objective: Solid-liquid separation

Ii. Recommended Equipment: Chamber Filter Press (2 units of 1500*1500 model)

The hydraulic automatic compression box filter press is equipped with a compression system composed of a filter press, a cylinder, a hydraulic oil pump and a control cabinet, which can achieve the pressure holding and pressure replenishment functions of the hydraulic system and ensure the operation of fluid filtration. The highly compressed pressure filter cake has a lower moisture content. It is used for solid-liquid separation of various suspensions, with good separation effect and convenient use.

Working principle of the equipment

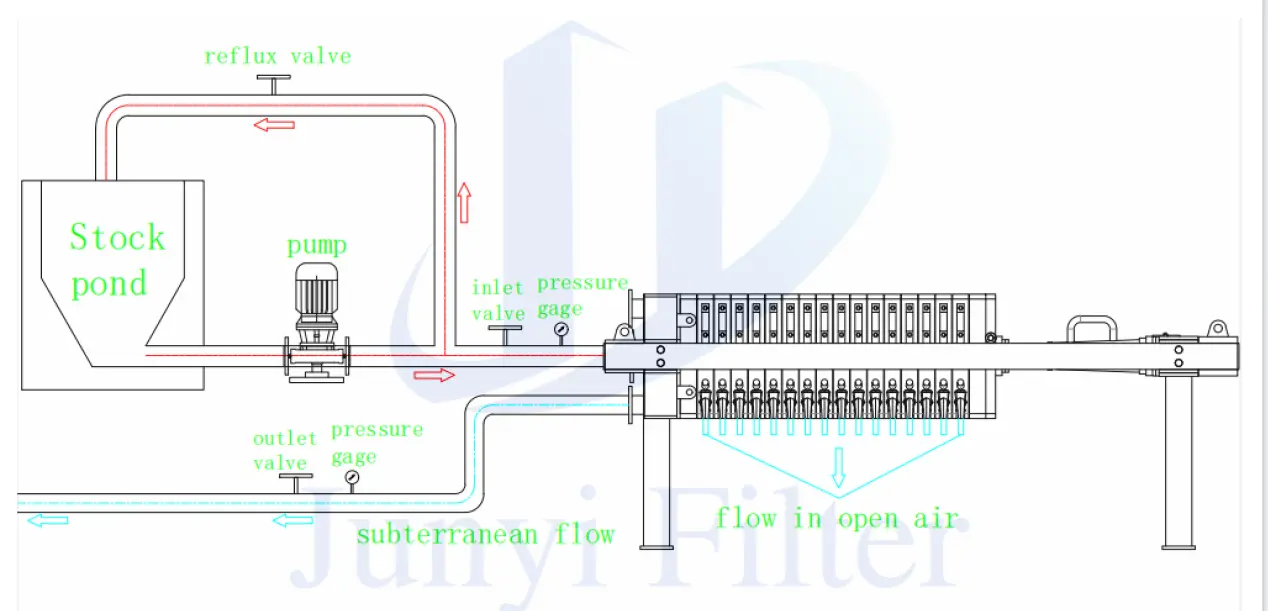

Under the pressure of the feed pump, the liquid material to be filtered is sent into each filter chamber. Through the filter cloth, the solid and liquid are separated. Filter residue is formed on the filter cloth until the filter chamber is filled to form a filter cake. The filtrate passes through the filter cloth and flows along the grooves of the filter plate to the lower liquid outlet channel, and is discharged centrally. After filtration is completed, clean washing water can be introduced to wash the filter residue.

Selection basis:

Selection basis: The customer's flow rate is 90m³/h and the working hours are 8 hours a day. The total volume of liquid processed is 720 cubic meters. From feeding to discharging the slag to complete one working cycle, calculated at 2 hours, with an 8-hour working day, a total of 4 slag discharges are required. One filtration process requires processing 180 cubic meters of liquid, with a solid mass of 21.6 cubic meters. As the density of marble is higher than that of water, calculated at 2.5, the volume of the filter chamber needs to be 8,640 liters. The ratio of the filtration area to the volume of the filter chamber is usually 1:15. So a total of 576 square meters of filtration area is required. A 600-square-meter filter press takes up a very large area. Both the equipment and transportation costs are very high and cannot be accommodated in containers. Considering previous cases, in this situation, the customer will choose two machines with the same filtration area.

Based on this, we have selected two filter presses with a filtration area of 300 square meters for you.

Cost advantage

Processing capacity doubling: Suitable for high-flow suspension treatment, scenarios requiring continuous or large-scale processing.

The filtration area of a single 300㎡ filter press is 300 square meters. When two are operated in parallel, the total filtration area reaches 600 square meters. If the material properties are stable, under the same pressure and time, the theoretical processing capacity can be increased to twice that of a single unit

Shorten the cycle period

If the "alternating operation" mode (one filtering while the other is unloading/cleaning) is adopted, 24-hour uninterrupted production can be achieved, avoiding the downtime of a single device caused by unloading. For example:

Two units operate alternately: one batch is completed per hour (filtration and unloading are carried out simultaneously), with an efficiency increase of 50%.

Save the cost of the feed pump: Two filter presses can share the hydraulic station or feed pump, and the overload of a single device can be avoided through pressure balance control.

Liquid outlet method - Open flow: Faucets are installed under the left and right sides of each filter plate, and a water collection trough is also provided. The non-recycled liquid adopts open flow.

Junyi Copyright ? 2025 ALL rights reserved