News

In the current context where global competition in the chemical industry is becoming increasingly fierce, a reactor with outstanding performance and strong adaptability has become a key tool for enterprises to enhance their core competitiveness. Recently, our company, relying on its profound technological accumulation and innovative service concepts, has successfully collaborated with a Russian client to customize a 316 stainless steel reaction vessel for them. Currently, this order has entered the intense production and manufacturing stage, attracting widespread attention from the industry. ?

The Russian client mainly engages in the research and development and production of fine chemical products. This new project involves complex chemical synthesis reactions and has extremely strict requirements for the material, sealing performance, temperature control method and pressure control of the reaction vessels. Considering the strong corrosiveness of the reaction materials and the particularity of the reaction process, the customer explicitly proposed to use 316 stainless steel to build the reaction vessel to ensure that the equipment has excellent corrosion resistance. Meanwhile, the reaction process needs to be carried out in a negative pressure environment. It is required that the reaction vessel can stably maintain a negative pressure state of -0.1MPa, and the sealing performance must reach the top industry standards to eliminate any leakage risks. In addition, the temperature control accuracy required for the reaction is extremely high. The customer hopes to achieve precise temperature control by heating with hot oil. Facing such a highly challenging demand, the client screens suppliers from multiple sources worldwide, striving to find a competent partner. ?

Upon learning of the demands of the Russian client, our company responded promptly and immediately formed an elite task force consisting of chemical process experts, mechanical design engineers, and material analysts. The team immediately engaged in in-depth communication with the client, not only thoroughly understanding the client's production process, reaction procedures and specific technical indicators, but also conducting in-depth research on local industrial standards and regulations in Russia to ensure that the design plan not only meets the client's needs but also complies with local norms.

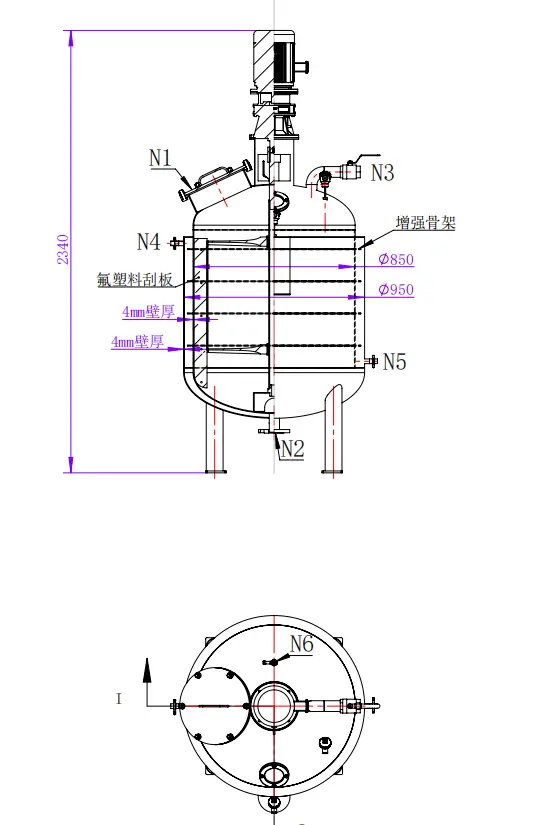

During the design stage, the team fully leveraged their technical advantages and utilized advanced 3D modeling software to meticulously draw the design drawings of the reaction vessel. The drawings precisely present everything from the overall structure to the detailed components, including the dimensions of the reactor body, the positions of each interface, and the layout of the internal stirring device, allowing the customer to have a clear understanding of the structure of the reaction reactor at a glance. Meanwhile, in response to the sealing performance that the customer is particularly concerned about, the team adopted a composite sealing structure design combining dual mechanical seals and lip seals, and detailedly marked the sealing principle and key parameters in the drawings to ensure that the reaction vessel can still maintain a high level of sealing even in a negative pressure environment of -0.1MPa. ?

In terms of temperature control and pressure control, the team, after numerous discussions and simulations, determined the hot oil circulation heating system and the intelligent pressure regulation scheme. The hot oil heating system ensures that the reactor can be heated up rapidly and evenly and maintain a stable reaction temperature by precisely calculating the heat exchange area and the flow rate of hot oil. The intelligent pressure control system is equipped with high-precision sensors and automatic regulating valves to monitor the pressure changes inside the reaction vessel in real time. Once the pressure deviates from the set value, the system will immediately adjust automatically to ensure that the negative pressure remains stable at -0.1MPa. In addition, considering the 500L volume of the reaction vessel, the team repeatedly calculated and optimized the strength and stability of the vessel body. They adopted thickened 316 stainless steel plates and rationally designed the reinforcing rib structure to ensure the safe and reliable operation of the equipment under complex working conditions. ?

When the complete design drawings and technical solutions were presented to the Russian client, the client was full of praise for our professional ability and rigorous attitude. The fineness of the design drawings, the scientific nature of the technical solutions, and the precise grasp of customer needs all far exceeded their expectations. After several rounds of in-depth communication and detailed confirmation, both sides successfully signed the cooperation order. ?

At present, this 316 stainless steel reaction vessel has entered the intense manufacturing stage in our production workshop. The production team strictly adheres to the design drawings and process standards, meticulously controlling every production link. From sheet cutting, welding and forming to equipment assembly, commissioning and testing, each process undergoes strict inspection to ensure that the final delivered reaction vessel meets or even exceeds the customer's expectations. ?

This cooperation with the Russian client marks another milestone for Shanghai Junyi Filtration Equipment Co., Ltd. in the field of high-end customized reaction vessels. In the future, Shanghai Junyi will continue to focus on technological innovation, empower the development of global chemical enterprises with higher-quality products and services, and write more brilliant chapters of cooperation in the international market. ?

Junyi Copyright ? 2025 ALL rights reserved